Mahler AGS GmbH

Mahler AGS is a leading international company specialized in process and detailed engineering, manufacturing, module building, and providing high quality, safe, and reliable gas generation and purification plants for different gases.

The Mahler AGS gas generation units, which include hydrogen plants, oxygen plants, nitrogen plants, or protective gas plants, come with a unique design that enables them to be available over 98% of the year or more than 8600 hours per year.

Proactive service and support at all stages of plant life is provided to our Clients through Mahler’s philosophy of finding the most suitable solution for our Client’s needs through close contact and long-term cooperation.

Mahler has a comprehensive, fully end to end project management and delivery which offers concept studies, FEED, EPF, EPC, multi-disciplinary engineering, procurement, logistics and complete CE certification for our plants.

Our experienced and competent field engineers ensure the correct and proper installation of the plant starting from final check of erection and mechanical completion until performance test. We provide all commissioning services, which includes catalyst and adsorbent loading of reactors and vessels, carrying out numerous function tests, plant startup, adjustment of process parameters and check of all safety functions. Our dedicated service team continues to provide consultation and service throughout the plant lifetime, with on-site and remote access, inspections, upgrades and other services including the proposal and supply of spare parts. It is this proven quality and reliability that has allowed many Mahler plants to be operated for 40+ years.

Our Technology

Our engineering team is by your side from project concept to realization, understanding that each application and location is unique.

Mahler’s top-fired co-current reformer technology is at the heart of our hydrogen generation and purification plants, together with a multibed Hydrogen Pressure Swing Adsorption (PSA) system HYDROSWING that is incorporated into both our HYDROFORM-C and HYDROFORM-M plants. These can handle the recovery and purification of hydrogen from different hydrogen-rich gases coming from steam reforming, methanol reforming or from various refinery or petrochemical off-gases.

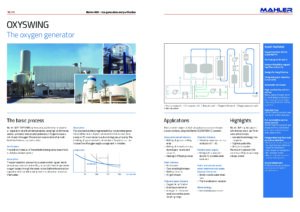

Mahler’s Oxygen PSA and Vacuum Pressure Swing Adsorption (VPSA) system OXYSWING employ the basic principle of air separation at ambient temperatures using high performance zeolite, a material that preferably adsorbs nitrogen to leave a rich stream of oxygen.

Mahler also supplies PSA separation units for Biogas upgrading and process gas purification and separation.

Product Portfolio

Hydrogen Generation (H2): HYDROSWING, HYDROFORM-C, HYDROFORM-M

Oxygen Generation (O2): OXYSWING

Nitrogen Generation (N2): NITROSWING

Biogas upgrading systems: BIOSWING

Process Gas: Protective gas generators and multi-bed PSAs, PERMAGS-PRO

Business Details

Address

- Hedelfinger Str. 60

- Stuttgart, 70327

- Germany

Contact

- Tel: +49 711 870300

- Fax: +49 711 87030-200

- www.mahler-ags.com

- [email protected]

Share

Categories

- Air Separation Plant

- Gas Production Plant

- Hydrogen Plant / Generators

- Medium/Large Reformer Hydrogen Plant

- Membrane Hydrogen Plant

- Nitrogen Plant / Generators

- Non-Cryogenic Air Separation Plant

- Oxygen Plant / Generators

- Pressure Swing Adsorption Hydrogen Plant

- Pressure Swing Adsorption Oxygen Plant

- Small Reformer Hydrogen Plant

- Syngas Plant

- VPSA Oxygen Plant